- Steam traps

- Pressure regulators

- Control valves

-

- Control valves

- Two-way control valves

- Three-way control valves

- two-way on/off globe valves

- Intermittent blowdown valves & TDS blowdown control valves

- Pneumatic and electric linear actuators

- Universal controllers, transmitters, temperature sensors, digital panel, pneumatic and electric positioners

- Self-acting temperature control valves

- Two-way overflow valves

- Boiler house and special equipment

-

- Boiler house and special equipment

- Separators steam and compressed air

- Shell and tube & plate heat exchangers

- Sample coolers

- Direct steam injectors

- Flash vessels with inbuilt steam trap

- Blowdown expansion and cooling units in boiler houses

- Exhaust heads

- Hot condensate coolers

- Condensate lifting pots

- Steam-water mixers & Water-saving guns

- Level gauges & Magnetic level indicators

- Pressure operated pumps and packaged pump units

- Pipeline ancillaries

- Packaged units / Skids

- Clean steam equipment

-

- Clean steam equipment

- Clean Steam Generator

- Thermostatic clean steam traps

- Clean Service Control Valves

- Sanitary pressure regulators

- Clean Steam Separators

- Culinary steam filters

- Hygienic steam filters

- Clean Service Safety Valves

- Hygienic vacuum breakers

- Sample cooler clean steam

- Clean steam injectors

- Direct steam injection humidifiers

- Mushroom style air vent

- Three piece hygienic ball valves

- Three piece high purity ball valves

- Sanitary sight glass

- Sanitary pressure gauges

- Sanitary air vent valves

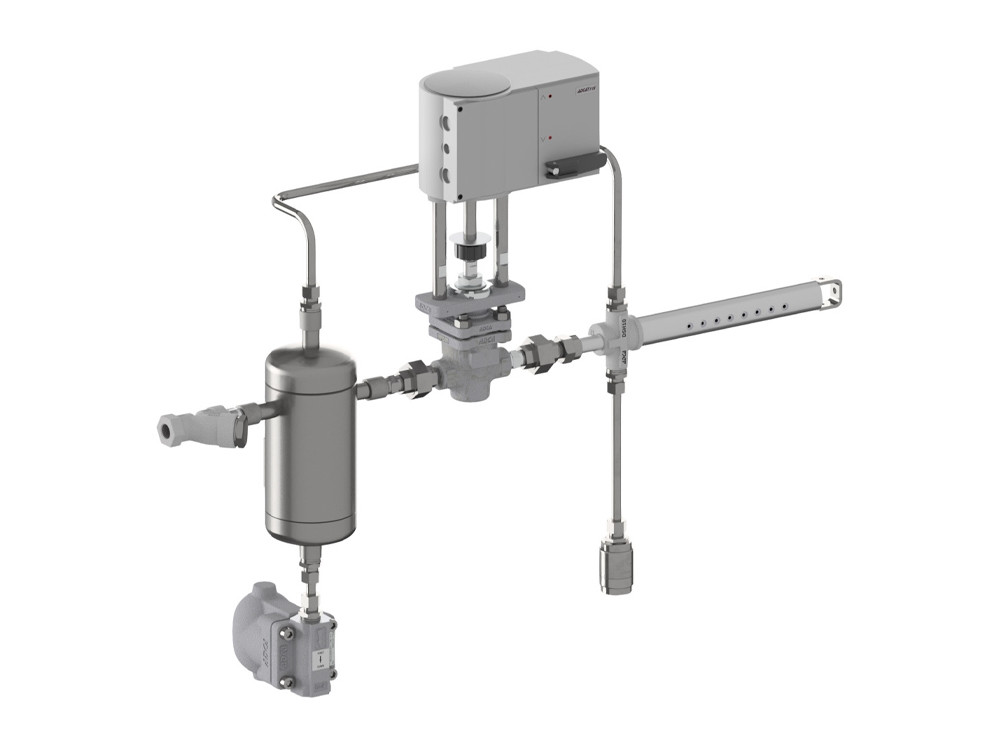

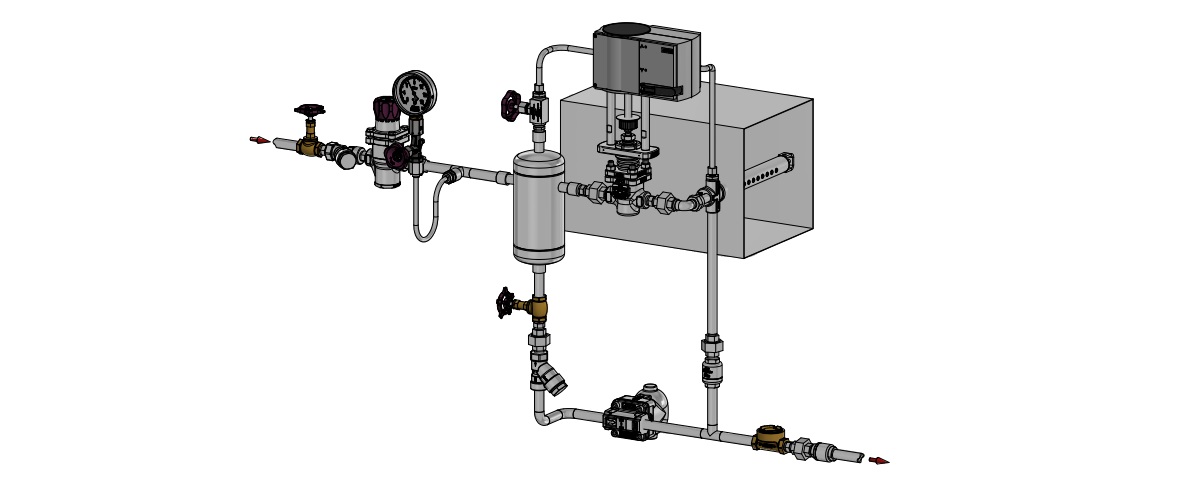

Direct steam injection humidifiers ADCA DSH

|

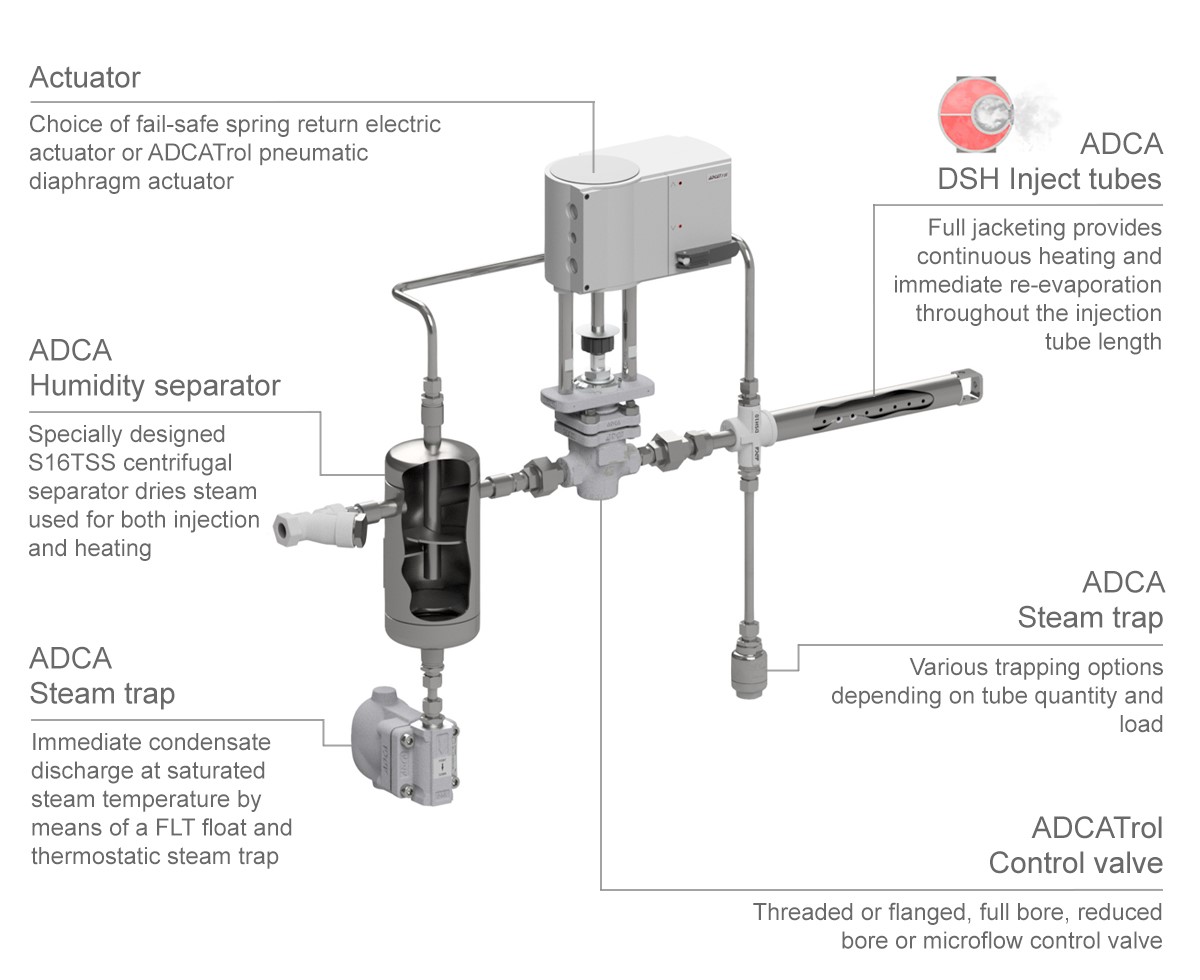

Designed to ensure highly efficient and moisture-free steam injection in air ducts and AHU for humidification purposes.

Manufactured as a bespoke solution to meet flow requirements and duct size/configuration with single or multiple injection tube for low absorption distances.

OPERATION

Steam moves in the supply line passing through a strainer to remove solid particles and, if necessary, through a pressure reducing valve to reduce it to humidification pressure (generally around 1 to 2 barg). Steam then passes through a S16TSS centrifugal humidity separator which removes any remaining finer particulate matter and most moisture content. The separator special design dries the steam which is injected and also the steam which feeds the heating chamber keeping heating temperatures stable. As steam leaves the humidity separator and passes through the jacketed injection tubes it is kept at a constant temperature, preventing condensation to be carried over with the steam.

Condensate collects on the bottom of the separator and is removed from the system at saturated temperature via a FLT float and thermostatic steam trap. Condensate which forms inside the injection tube heating chamber is removed by means of one or multiple steam traps depending on the case.

An ADCATrol globe control valve equipped with a fail-safe electric or pneumatic actuator provides accurate modulation of flow and, thus, precise humidity control.

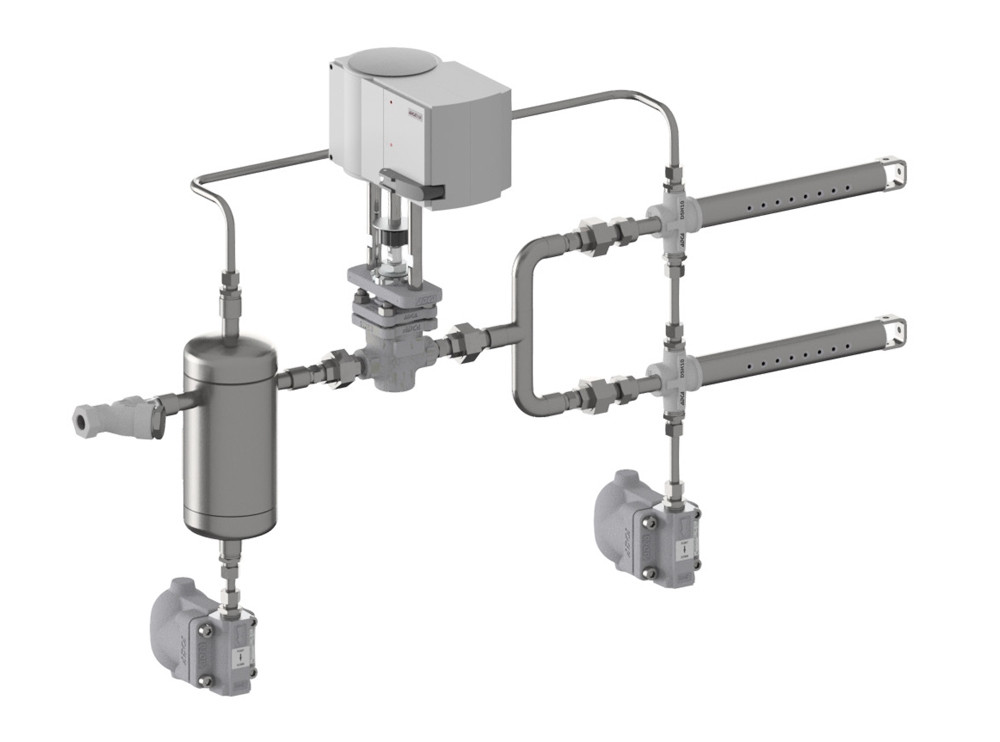

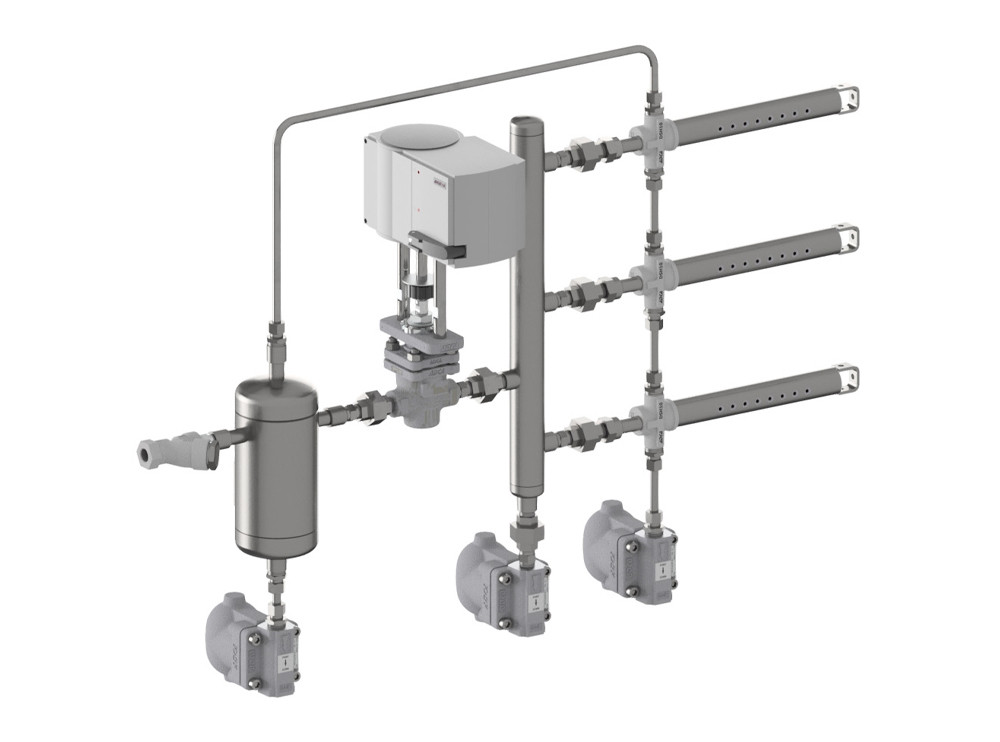

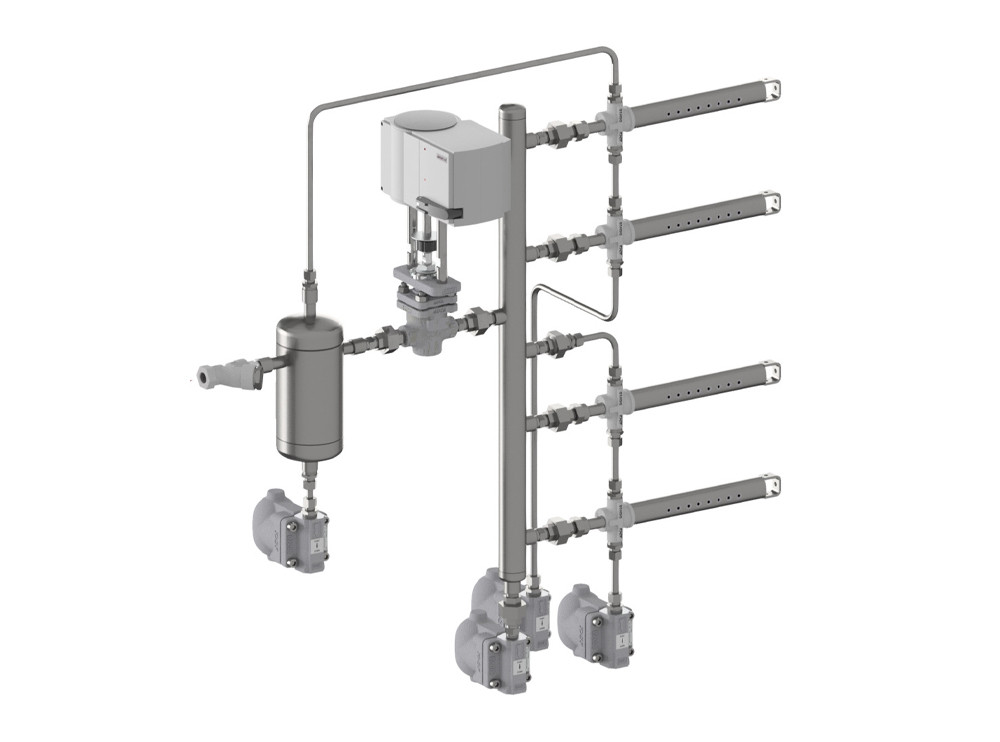

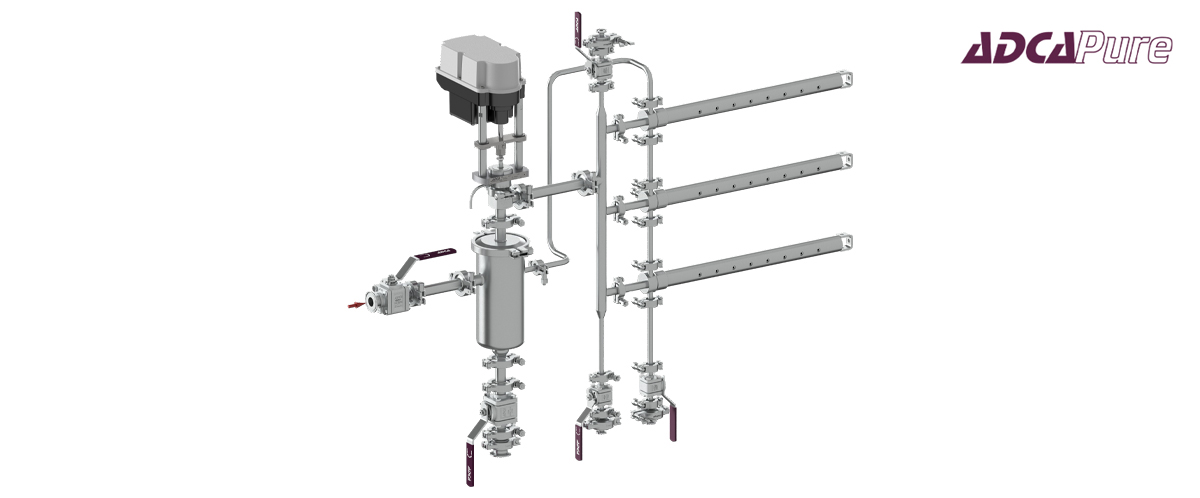

CONDENSATE DRAINAGE CONFIGURATIONS FOR MULTI-TUBE HUMIDIFIERS

Remarks: The number of injection tubes may vary. Images above are merely indicative. The size of the injection tube manifold must always be greater than the nominal size of the upstream humidity separator.

A single-tube humidifier is the most economically viable solution if a single injection tube respects the humidification load and the higher absorption distance (generally associated with single-tube humidifiers) is lower than the distance to any obstacle downstream.

If on the other hand, the available distance is insufficient to accommodate the necessary absorption distance of a singletube solution or when duct height is significant then a multi-tube humidifier should be selected. This solution will shorten the necessary absorption distance by up to 4 times as the increase in injection points will decrease flow velocity and also promote an homogenous and efficient mixing.

|

Single tube humidifier.

|

|

||

|

With 3 injection tubes . Recommended when the sum of insertion lengths totals 7 meters or less.

|

With 4 (or more) injection tubes. Recommended when the sum of insertion lengths totals more than 7 meters.

|

Overview of the air humidification system at the stand

MAIN FEATURES ADCA DSH:

— Quiet and efficient.

— Complete stainless steel construction.

— Bespoke injection tubes to meet flow requirements and duct design.

— Fully jacketed injection tubes providing moisture free steam injection.

— Use of ADCA highly efficient and proven centrifugal separator specially designed for the application.

UNIQUE HYGIENIC DESIGN

When it comes to clean steam humidification the ADCAPure DSHS is the only true hygienic option.

|

DSHS |

The presence of chemicals used in water treatment of plant steam boilers which produce steam used in humidification systems can have toxic effects on human health. Regulations have come into force in some countries so that only clean steam is used for humidification purposes and, to meet such requirements, ADCA DSH direct steam humidifiers can be tailor-made for use with clean steam. These can be supplied with individual ADCAPure components or as plug and play packaged solutions.

|

MAIN FEATURES ADCAPURE DSHS:

— Internal wetted parts: ≤ 0,51 µm Ra – SF1.

— Hygienic design in 316L / 1.4404 stainless steel.

— Bespoke injection tubes to meet flow requirements and duct design.

— Fully jacketed injection tubes providing moisture free steam injection.

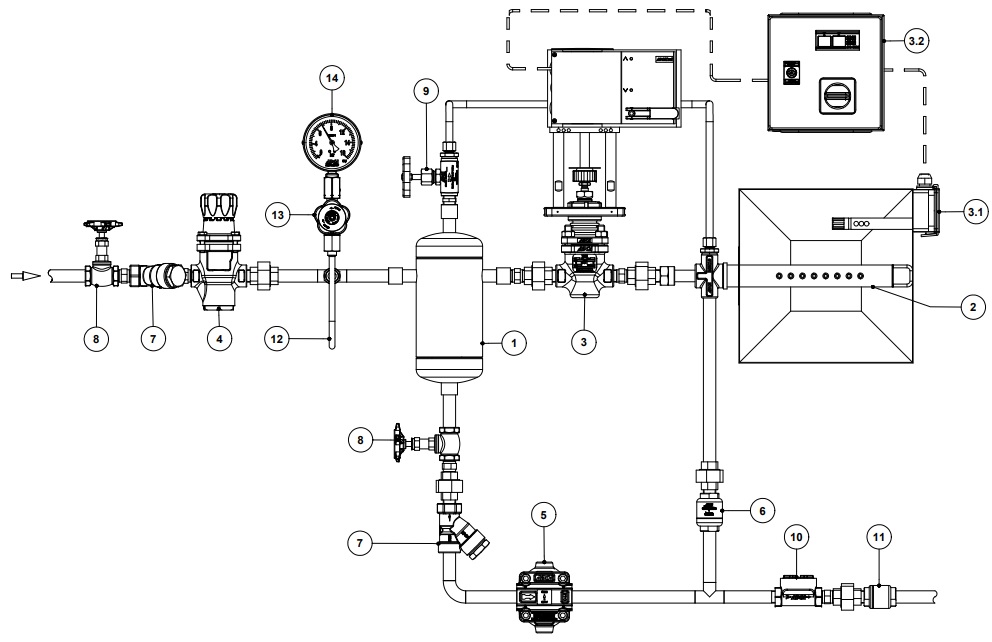

Let's take a look at a typical DSH steam and condensate humidification line diagram

It is necessary to ensure the quality of the steam (dryness) when it is supplied to the steam humidification system. It is also necessary to ensure proper drainage of the system. Along the steam path, it is necessary to ensure that condensate flows towards the drainage and make sure that there are no stagnant areas where it can accumulate.

|

|

POS. Nº |

Designation |

|

|

14 |

Pressure gauge ADCA MAN-100 |

|

|

13 |

Gauge cock ADCA GC-400 |

|

|

12 |

Gauge Siphon ADCA GSC-40 |

|

|

11 |

Non return valve ADCA RТ25 |

|

|

10 |

Single window sight glass ADCA SW12 / DW40SS |

|

|

9 |

Needle valve ADCA NV-400 |

|

|

8 |

Globe valve ADCA GV32В |

|

|

7 |

Y-strainer ADCA IS100 |

|

|

6 |

Thermostatic steam trap ADCA ТSS22 |

|

|

5 |

Float and thermostatic steam trap ADСА FLT41 |

|

|

4 |

Pressure reducing valve ADСА PRV25i |

|

|

3.2 |

Humidity controler |

|

|

3.1 |

Humidity transmiter |

|

|

3 |

Two way control valve with electric actuator ADCATrol |

|

|

2 |

Direct steam injection humidifier ADCA DSН |

|

|

1 |

Humidify separator ADCA S16TSS |

|

Remarks: The number of injection tubes may vary. Images above are merely indicative.

Efficiency

|

|