- Steam traps

- Pressure regulators

- Control valves

-

- Control valves

- Two-way control valves

- Three-way control valves

- two-way on/off globe valves

- Intermittent blowdown valves & TDS blowdown control valves

- Pneumatic and electric linear actuators

- Universal controllers, transmitters, temperature sensors, digital panel, pneumatic and electric positioners

- Self-acting temperature control valves

- Two-way overflow valves

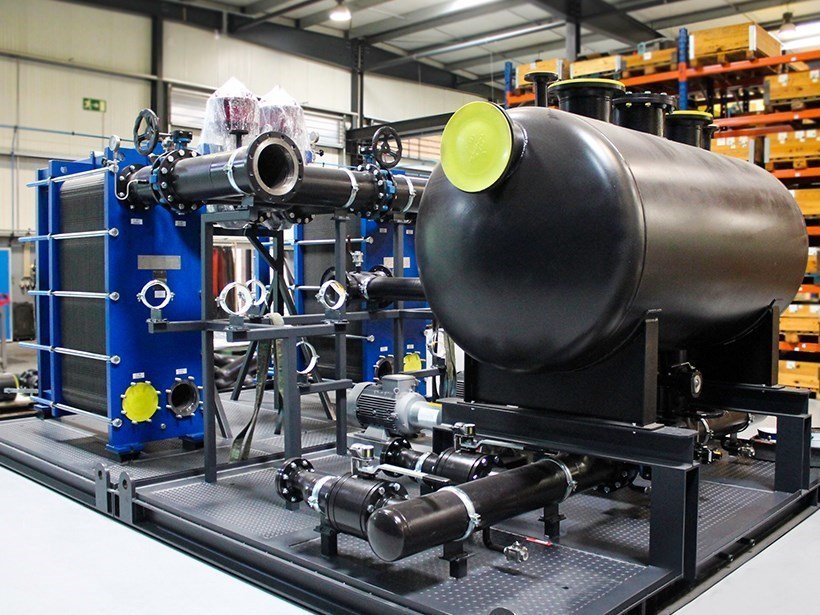

- Boiler house and special equipment

-

- Boiler house and special equipment

- Separators steam and compressed air

- Shell and tube & plate heat exchangers

- Sample coolers

- Direct steam injectors

- Flash vessels with inbuilt steam trap

- Blowdown expansion and cooling units in boiler houses

- Exhaust heads

- Hot condensate coolers

- Condensate lifting pots

- Steam-water mixers & Water-saving guns

- Level gauges & Magnetic level indicators

- Pressure operated pumps and packaged pump units

- Pipeline ancillaries

- Packaged units / Skids

- Clean steam equipment

-

- Clean steam equipment

- Clean Steam Generator

- Thermostatic clean steam traps

- Clean Service Control Valves

- Sanitary pressure regulators

- Clean Steam Separators

- Culinary steam filters

- Hygienic steam filters

- Clean Service Safety Valves

- Hygienic vacuum breakers

- Sample cooler clean steam

- Clean steam injectors

- Direct steam injection humidifiers

- Mushroom style air vent

- Three piece hygienic ball valves

- Three piece high purity ball valves

- Sanitary sight glass

- Sanitary pressure gauges

- Sanitary air vent valves

About ADCA brand

|

|

|||

ADCAPure - a unique line of equipment for clean steamADCAPure is a unique line of equipment for clean steam and sterile environments from Valsteam. You can find a list of this equipment and electronic versions of the data sheets on our website in the section: Clean steam equipment .

ADCAPURE CERTIFICATESOur quality system is certified by ISO 9001:2015 and guarantees the control of all the processes involved in the project, manufacturing and supply of our products. Various certificates and declarations can be supplied to attest the conformity of the products.. |

In partnership with Valsteam ADCA Engineering SA.

In partnership with Valsteam ADCA Engineering SA.

Portugal

the company has established the production of quality products. The wide range of equipment includes all major types of steam traps, pressure regulators, pneumatic and electric pressure reducing valves, condensate pumps, separators and other elements of steam and condensate pipelines. Due to their high quality and reasonable prices, Valsteam ADCA Engineering products are in great demand not only in Ukraine and European countries, but also all over the world. Each part and unit of the equipment is manufactured at the company's plant, which allows for full control over the quality of the products.

the company has established the production of quality products. The wide range of equipment includes all major types of steam traps, pressure regulators, pneumatic and electric pressure reducing valves, condensate pumps, separators and other elements of steam and condensate pipelines. Due to their high quality and reasonable prices, Valsteam ADCA Engineering products are in great demand not only in Ukraine and European countries, but also all over the world. Each part and unit of the equipment is manufactured at the company's plant, which allows for full control over the quality of the products. Quality control takes place at every stage of production. The most effective technologies and modern developments are used for this purpose. Despite the high quality, Valsteam ADCA Engineering products are distinguished by an affordable price that will satisfy even the most economical consumer.

Quality control takes place at every stage of production. The most effective technologies and modern developments are used for this purpose. Despite the high quality, Valsteam ADCA Engineering products are distinguished by an affordable price that will satisfy even the most economical consumer.

Reliable and high-quality materials are used for the production of products, which is why the products are characterized by a long service life and durability. Pipe fittings do not require frequent maintenance and can operate for a long time.

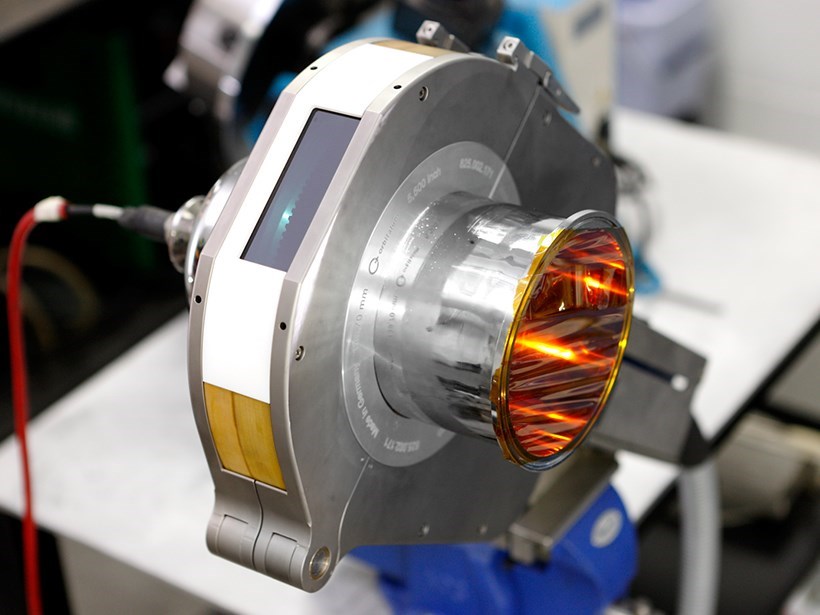

In 2012, Valsveam ADCA built three test benches. In 2019 ADCA decided to take it to the next level and create a 300m2 modern test bench & training facility which serve for both product testing and development and the location where our practical ADCATraining sessions take place.

In 2012, Valsveam ADCA built three test benches. In 2019 ADCA decided to take it to the next level and create a 300m2 modern test bench & training facility which serve for both product testing and development and the location where our practical ADCATraining sessions take place.Our training courses are strategically organized to provide the right knowledge depending on your needs. We make our know-how available, so you can come up with the best innovative solutions for your systems or customers. From technical classes to practice-oriented training sessions in our modern training facilities, we have everything you need.

WE PROVIDE: Steam and fluid masterclasses; Products master classes ADCA; Maintenance, servicing and repair workshop; Steam and condensate system analysis.

WE PROVIDE: Steam and fluid masterclasses; Products master classes ADCA; Maintenance, servicing and repair workshop; Steam and condensate system analysis.Valsteam ADCA Engineering also offers a unique line of equipment for clean steam and sterile environments, ADCAPure.

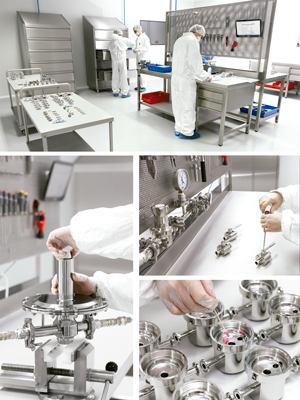

As our range kept on growing, the need to create a dedicated brand of products for clean steam, filtered air, purified water and many other “clean utility” mediums. We committed ourselves and ADCAPure was born, the range of products designed for the pharmaceutical, food, fine chemical and cosmetic industries.

All our ADCAPure products are cleaned, assembled and testing in ISO 14644-1 certified clean rooms. The Valsteam ADCA Eng. plant, one of the few in the world, also has a separate laboratory for testing clean steam equipment certified in accordance with ISO 14644-1.

The room is divided into four areas:

ULTRASOUND CLEANING ROOM. Equipped with fully automated ultrasonic cleaning machinery that uses a special degreasing method for oxygen and passivation applications;

ULTRASOUND CLEANING ROOM. Equipped with fully automated ultrasonic cleaning machinery that uses a special degreasing method for oxygen and passivation applications;HYGIENE CHAMBER. Room for disinfecting staff and putting on the necessary PPE;

ASSEMBLY ROOM. Room for assembling, testing and packing equipment. Equipped with tools and stainless steel furniture;

STORAGE. For final storage of the product in a contamination-free environment.

This equipment, which is used in the pharmaceutical, cosmetic and food industries, meets the following requirements:

This equipment, which is used in the pharmaceutical, cosmetic and food industries, meets the following requirements:Self-drainable design;

Special connections are used (for example, ASME BPE);

Special connections are used (for example, ASME BPE);Easy access for cleaning;

High quality polishing and surface treatment;

Made of high quality stainless steels;

The quality of components (seals, diaphragms, diaphragms, etc.) meets special material requirements.

Production technology

Warranty obligationsThe manufacturer Valsteam ADCA Engineering (Portugal), represented by our company Prima Trading, the official representative in Ukraine, guarantees free repair and/or replacement of the equipment during the warranty period, except in cases where defects and breakdowns occurred due to the fault of the consumer and are related to violation of the rules of transportation, storage, installation and/or operation specified in the relevant documents, as well as the impossibility of unambiguous identification of the equipment and/or the fact of shipment. The standard warranty period is 12 months.The warranty period starts from the date of shipment of the equipment from our warehouse, which is confirmed by the relevant documents.

Service, warranty and post-warranty maintenance:• Equipment maintenance. |

Our advantages of cooperation with partners• Make your work easier and more convenient with our materials: from catalogs and 3D models to technical diagrams and solutions. |

Technology

As a “one-stop-shop” and a full-service manufacturer, we assure the complete production cycle: design, machining, welding, assembly, tests, quality, and packaging. A complex system that depends on the high technology we use.

As a “one-stop-shop” and a full-service manufacturer, we assure the complete production cycle: design, machining, welding, assembly, tests, quality, and packaging. A complex system that depends on the high technology we use.

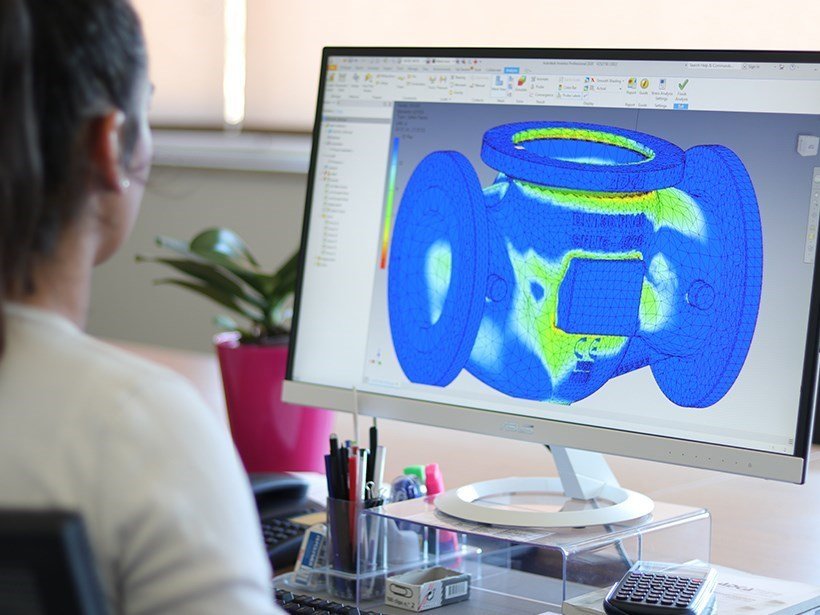

Research and development

Research and development

We are innovators by nature, always researching and developing effective solutions and products. The development of our products begins in our design and engineering departments, where out teams of designers and engineers use advanced engineering software and acquired knowhow.

Welding

Several welding procedures such as orbital, manual and mechanized TIG, MMA (stick welding), MAG and micro plasma arc are carried out by experienced and qualified welders. Stainless steel and ADCAPure weldings are performed in a dedicated contamination free environment to ensure the highest standard.

Several welding procedures such as orbital, manual and mechanized TIG, MMA (stick welding), MAG and micro plasma arc are carried out by experienced and qualified welders. Stainless steel and ADCAPure weldings are performed in a dedicated contamination free environment to ensure the highest standard.

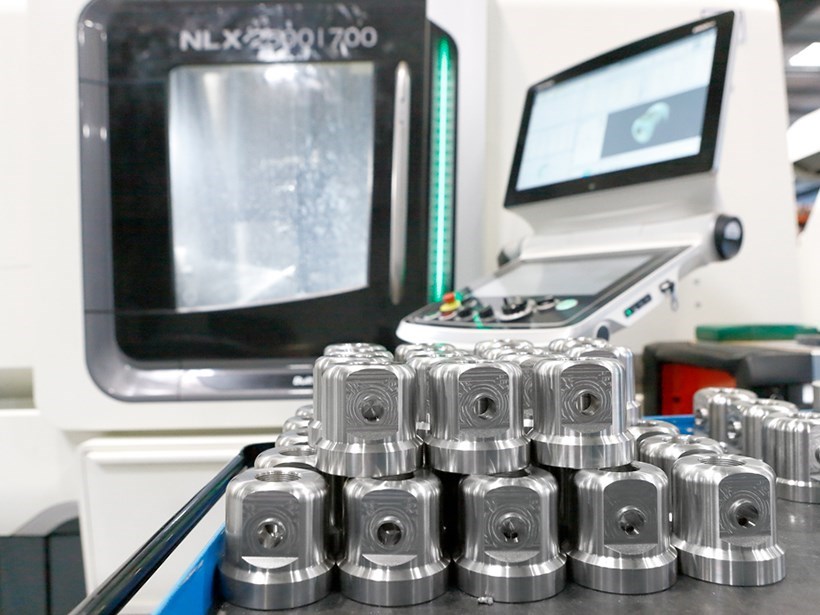

Machining

The strong investment in state of the art machinery allows us to achieve a high level of quality and reliability, as well as a natural increase in productivity and decrease in delivery times, specially for non-standard series of products.

Machining

Most of the components used on our products must be submitted to grinding, burnishing, lapping, polishing and other operations. These finishing processes are handled by specialized personnel and controlled by our quality department in our laboratory, supported by the most modern metrology and testing equipment.

Most of the components used on our products must be submitted to grinding, burnishing, lapping, polishing and other operations. These finishing processes are handled by specialized personnel and controlled by our quality department in our laboratory, supported by the most modern metrology and testing equipment.

Quality control & tests

Products are meticulously tested and rigorously controlled throughout the manufacturing process granting the highest level of quality and reliability. From raw material control via spectometry and 3D measuring to final product testing.

Assembly

It's the place where we assemble all the components, where craftsmanship and technology come together to obtain the final result. Here ADCA products become ready for battle!

Marking

Laser marking, tagging, engraving...

these are some of the technologies we use on a daily base to carefully identify our products, and guaranty its future traceability.

Packaging

In Valsteam we give our best to properly package our goods, protecting them from damage during transport and storage.