- Steam traps

- Pressure regulators

- Control valves

-

- Control valves

- Two-way control valves

- Three-way control valves

- two-way on/off globe valves

- Intermittent blowdown valves & TDS blowdown control valves

- Pneumatic and electric linear actuators

- Universal controllers, transmitters, temperature sensors, digital panel, pneumatic and electric positioners

- Self-acting temperature control valves

- Two-way overflow valves

- Boiler house and special equipment

-

- Boiler house and special equipment

- Separators steam and compressed air

- Shell and tube & plate heat exchangers

- Sample coolers

- Direct steam injectors

- Flash vessels with inbuilt steam trap

- Blowdown expansion and cooling units in boiler houses

- Exhaust heads

- Hot condensate coolers

- Condensate lifting pots

- Steam-water mixers & Water-saving guns

- Level gauges & Magnetic level indicators

- Pressure operated pumps and packaged pump units

- Pipeline ancillaries

- Packaged units / Skids

- Clean steam equipment

-

- Clean steam equipment

- Clean Steam Generator

- Thermostatic clean steam traps

- Clean Service Control Valves

- Sanitary pressure regulators

- Clean Steam Separators

- Culinary steam filters

- Hygienic steam filters

- Clean Service Safety Valves

- Hygienic vacuum breakers

- Sample cooler clean steam

- Clean steam injectors

- Direct steam injection humidifiers

- Mushroom style air vent

- Three piece hygienic ball valves

- Three piece high purity ball valves

- Sanitary sight glass

- Sanitary pressure gauges

- Sanitary air vent valves

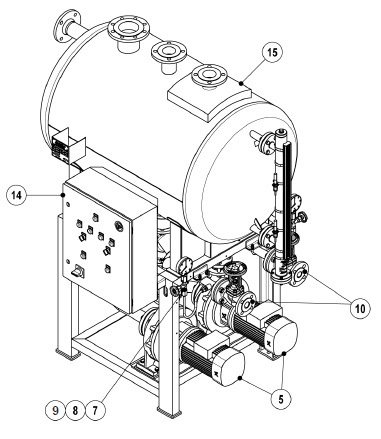

Electric condensate recovery units PRIMA-THERM ESVK

Specifications

Documentation

DESCRIPTION:

The PRIMA-THERM ESVK series electric condensate recovery units are recommended in the transfer of high-temperature water such as hot condensate, to a higher elevation or pressure. This condensate is usually used as boiler feedwater. The standard models are prepared for flows up to 30 m³/h, or higher on request. The units are composed of an horizontal condensate vessel (receiver), a metallic support frame, electric pumps, level controls, valves, prewired control panel and pipework for connections between the different elements of the units..

OPERATION:

The condensate is brought into the vessel through the inlet connections, with stainless steel sparge pipes, located on the top of the vessel. As the condensate level rises it will trigger the level control system to start the pumping process. In normal operating conditions, the pumps will work in alternating mode, which means they will alternate duty at the end of each cycle. In the event of a peak load, the level will continue rising eventually triggering the cascading switch which will make both pumps work simultaneously to relieve this peak demand.

MAIN FEATURES:

Condensate vessel – Completely manufactured from AISI 316 stainless steel or carbon steel, with inlet connections, overflow, air vents, drain, pump feeding outlets and a magnetic level indicator with bi-stable switches.

Pipework, valves and ancillaries – Includes full bore ball valves at the pump suction ports, manual regulating valves for system head regulation at the pumps discharge, pipework, strainers and pressure gauges.

Metal frame – Manufactured from structural steel (sandblasted and painted) or stainless steel (sandblasted).

Pumps – Manufactured from cast iron or stainless steel, capable of handling hot condensate up to 98 ºC and designed for low NPSH.

Control panel – Metal enclosure rated to IP 65 or higher. Features alternating and cascading (simultaneity) functions, pump fault indication for each pump, low and high-level alarms, pump dry run inhibitor, operating mode selector switch and volt-free telemetry terminals for remote stats.

The unit requires a 3 phase, 380 to 415 V AC, 50 Hz power supply.

Vessel capacity:

225 liters

600 liters

850 liters

Vessel material:

Carbon steel P235GH / 1.0325

Stainless steel AISI 316 / 1.4401

Number of electric pumps:

Single pump (non standard) (3~ 380 to 415 V, 50 Hz)

Two pumps (3~ 380 to 415 V, 50 Hz)

Maximum flow rate and delivery head in meters at the mentioned flow:

2 m³/h at 10 metres (with 225 L vessel)

4 m³/h at 10 metres (with 225 L vessel))

10 m³/h at 10 metres (with 600 L vessel)

10 m³/h at 20 metres (with 600 L vessel)

10 m³/h at 30 metres (with 600 L vessel)

20 m³/h at 10 metres (with 600 L vessel)

30 m³/h at 10 metres (with 850 L vessel)

30 m³/h at 20 metres (with 850 L vessel)

Metal frame:

Fabricated carbon steel S235JR/1.0038

Fabricated stainless steel AISI304/1.4301

Control panel:

Without control panel

Control panel enclosure, magnetic level indicator, bi-stable switches and wiring

Thermal insulation:

Without thermal insulation

Thermal insulation with aluminium cladding

AVAILABLE MODELS:

EC225 2T10 – 225L vessel capacity, 2 m³/h flow rate and 10 m delivery head.

EC225 4T10 – 225L vessel capacity, 4 m³/h flow rate and 10 m delivery head.

EC600 10T10 – 600L vessel capacity, 10 m³/h flow rate and 10 m delivery head.

EC600 10T20 – 600L vessel capacity, 10 m³/h flow rate and 20 m delivery head.

EC600 10T30 – 600L vessel capacity, 10 m³/h flow rate and 30 m delivery head.

EC600 20T10 – 600L vessel capacity, 20 m³/h flow rate and 10 m delivery head.

EC850 30T10 – 850L vessel capacity, 30 m³/h flow rate and 10 m delivery head.

EC850 30T20 – 850L vessel capacity, 30 m³/h flow rate and 20 m delivery head.

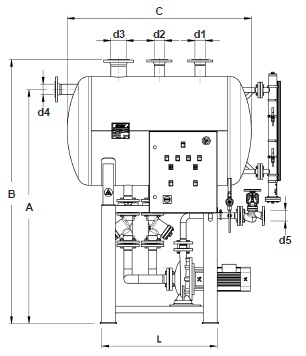

CONNECTIONS

|

MODEL |

d1 |

d2 |

d3 |

d4 |

d5 |

|

EC225 2T10 |

DN 50 |

DN 50 |

DN 80 |

DN 50 |

1”; DN 25 * |

|

EC225 4T10 |

DN 50 |

DN 50 |

DN 80 |

DN 50 |

11/2”; DN 40 * |

|

EC600 10T10 |

DN 65 |

DN 65 |

DN 100 |

DN 65 |

DN 32 |

|

EC600 10T20 |

DN 65 |

DN 65 |

DN 100 |

DN 65 |

DN 40 |

|

EC600 20T10 |

DN 65 |

DN 65 |

DN 100 |

DN 65 |

DN50 |

|

EC600 20T20 |

DN 65 |

DN 65 |

DN 100 |

DN 65 |

DN 32 |

|

EC850 30T10 |

DN 100 |

DN 100 |

DN 100 |

DN 100 |

DN 40 |

|

EC850 30T20 |

DN 100 |

DN 100 |

DN 100 |

DN 100 |

DN 50 |

* As standard flanged connections are EN 1092-1 PN 16 and female threaded connections are ISO 7 Rp. Flanged connections according to ASME B16.5 Class 150 and female threaded connections according to ASME B1.20.1 (NPT) are available on request..

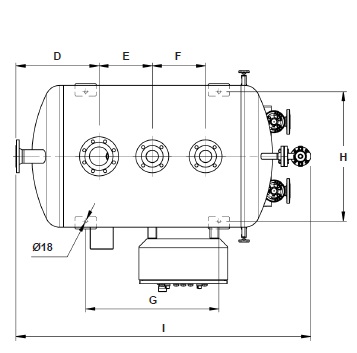

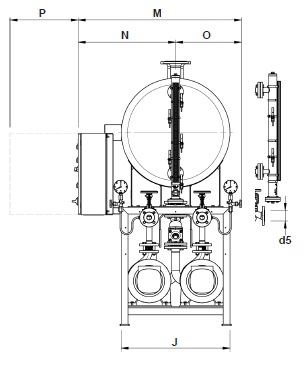

DIMENSIONS (mm)

|

MODEL |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

L |

M |

N |

O |

P |

|

EC225 |

1450 |

1645 |

1236 |

423 |

300 |

300 |

750 |

440 |

1577,5 |

500 |

830 |

827 |

577 |

250 |

500 |

|

EC600 |

1725 |

1945 |

1354 |

467 |

300 |

300 |

750 |

730 |

1660,5 |

800 |

850 |

1200 |

727 |

473 |

500 |

|

EC850 |

1700 |

1945 |

1854 |

617 |

400 |

400 |

1000 |

730 |

2160,5 |

800 |

1100 |

1200 |

727 |

473 |

500 |

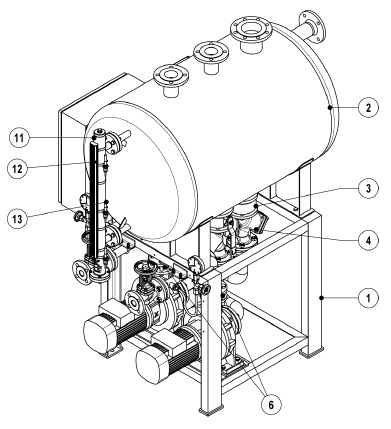

MATERIALS

|

POS. Nº |

DESIGNATION |

MATERIALS * |

|

1 |

Metal frame |

Carbon steel; |

|

2 |

Vessel |

Carbon steel; |

|

3 |

Ball valves |

(ICP Valves / Valsteam ADCA) |

|

4 |

Strainers |

(Valsteam ADCA / SFERACO) |

|

5 |

Electric pumps |

GRUNDFOS / WILO / SPERONI / Others on request |

|

6 |

Check valves |

(ICP Valves / Valsteam ADCA) |

|

7 |

Pressure gauge |

Valsteam ADCA / SFERACO |

|

8 |

Siphon |

Valsteam ADCA / PRIMA-THERM |

|

9 |

Gauge cock |

Valsteam ADCA / SFERACO |

|

10 |

Globe valve |

(ICP Valves / Valsteam ADCA) |

|

11,12 |

Magnetic level indicator / Indicator |

Valsteam ADCA / Others on request |

|

13 |

Level switch |

Valsteam ADCA / Others on request |

|

14 |

Control panel |

PRIMA-THERM |

|

15 |

Thermal insulation ** |

Thermal insulation with aluminium cladding / Others on request |

* References shown are merely indicative and can be changed without notice.

** Optional.