- Steam traps

- Pressure regulators

- Control valves

-

- Control valves

- Two-way control valves

- Three-way control valves

- two-way on/off globe valves

- Intermittent blowdown valves & TDS blowdown control valves

- Pneumatic and electric linear actuators

- Universal controllers, transmitters, temperature sensors, digital panel, pneumatic and electric positioners

- Self-acting temperature control valves

- Two-way overflow valves

- Boiler house and special equipment

-

- Boiler house and special equipment

- Separators steam and compressed air

- Shell and tube & plate heat exchangers

- Sample coolers

- Direct steam injectors

- Flash vessels with inbuilt steam trap

- Blowdown expansion and cooling units in boiler houses

- Exhaust heads

- Hot condensate coolers

- Condensate lifting pots

- Steam-water mixers & Water-saving guns

- Level gauges & Magnetic level indicators

- Pressure operated pumps and packaged pump units

- Pipeline ancillaries

- Packaged units / Skids

- Clean steam equipment

-

- Clean steam equipment

- Clean Steam Generator

- Thermostatic clean steam traps

- Clean Service Control Valves

- Sanitary pressure regulators

- Clean Steam Separators

- Culinary steam filters

- Hygienic steam filters

- Clean Service Safety Valves

- Hygienic vacuum breakers

- Sample cooler clean steam

- Clean steam injectors

- Direct steam injection humidifiers

- Mushroom style air vent

- Three piece hygienic ball valves

- Three piece high purity ball valves

- Sanitary sight glass

- Sanitary pressure gauges

- Sanitary air vent valves

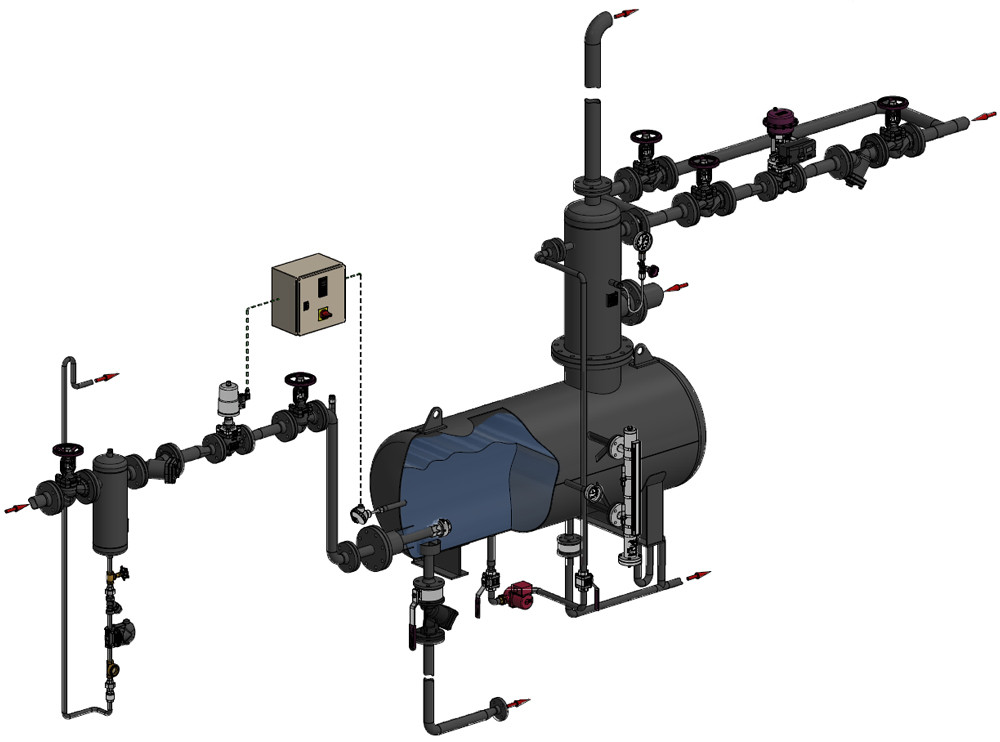

Automation Panel Deaeration Units PRIMA-THERM

Specifications

Documentation

Purpose of the automation panel: it is intended to maintain the parameters (pressure, temperature and level) within the range of set values. In this case, pressure control is carried out by adjusting the electric valves according to the algorithms stored in the PLC (programmable logic controller) memory.

Depending on the system configuration, both pulse and analog control of pressure, temperature, and liquid level is possible.

Functions implemented by the automation panel in the basic configuration:

- Applications: Maintaining the pressure, temperature, and level of liquids in the deaeration system within a specified range of values;

- Controlling the power supply of the deaeration system (COD, condensate, etc.);

- Functions for controlling the power supply of the deaeration system (COD, condensate, etc.).

Optional functions:

- Starting up the pump units via the “star-delta”;

- Switching on the pumping units by means of a soft start;

- Frequency control of condensate pumps;

- Dispatching and remote control of the pumping station via RS485, RS232, CAN bus, Ethernet information interface.

* Unitronics controllers are used as standard.