- Steam traps

- Pressure regulators

- Control valves

-

- Control valves

- Two-way control valves

- Three-way control valves

- two-way on/off globe valves

- Intermittent blowdown valves & TDS blowdown control valves

- Pneumatic and electric linear actuators

- Universal controllers, transmitters, temperature sensors, digital panel, pneumatic and electric positioners

- Self-acting temperature control valves

- Two-way overflow valves

- Boiler house and special equipment

-

- Boiler house and special equipment

- Separators steam and compressed air

- Shell and tube & plate heat exchangers

- Sample coolers

- Direct steam injectors

- Flash vessels with inbuilt steam trap

- Blowdown expansion and cooling units in boiler houses

- Exhaust heads

- Hot condensate coolers

- Condensate lifting pots

- Steam-water mixers & Water-saving guns

- Level gauges & Magnetic level indicators

- Pressure operated pumps and packaged pump units

- Pipeline ancillaries

- Packaged units / Skids

- Clean steam equipment

-

- Clean steam equipment

- Clean Steam Generator

- Thermostatic clean steam traps

- Clean Service Control Valves

- Sanitary pressure regulators

- Clean Steam Separators

- Culinary steam filters

- Hygienic steam filters

- Clean Service Safety Valves

- Hygienic vacuum breakers

- Sample cooler clean steam

- Clean steam injectors

- Direct steam injection humidifiers

- Mushroom style air vent

- Three piece hygienic ball valves

- Three piece high purity ball valves

- Sanitary sight glass

- Sanitary pressure gauges

- Sanitary air vent valves

- Main

- →

- Condensate collection and return units

- →

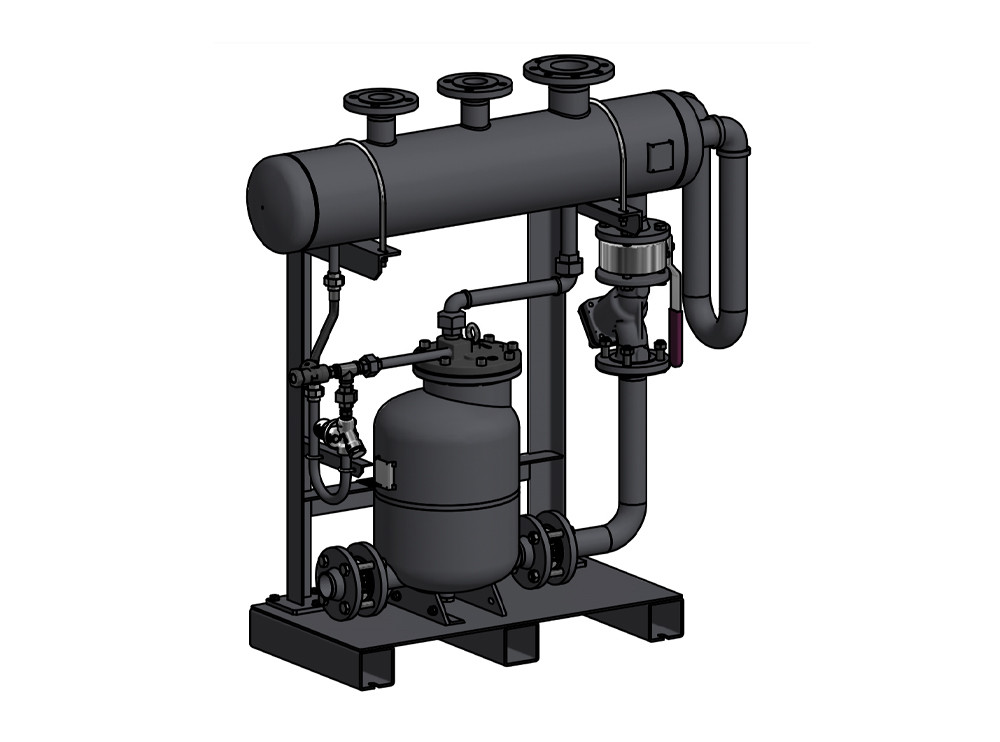

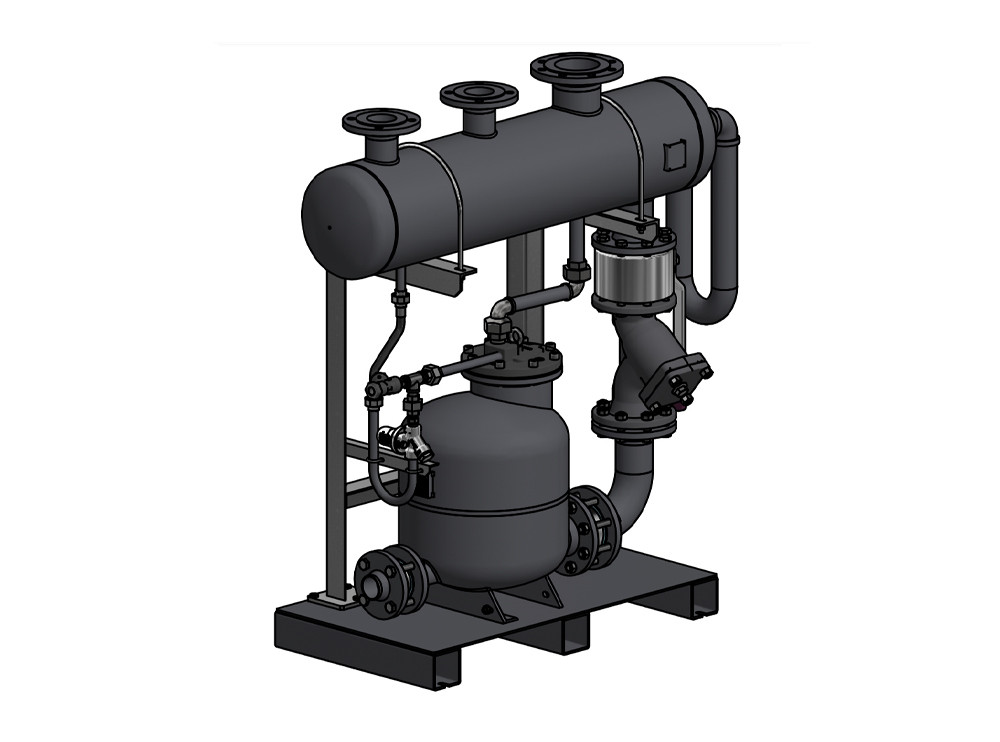

- Condensate collection and return units PRIMA-THERM MSVK-1 for steam systems

Condensate collection and return units PRIMA-THERM MSVK-1 for steam systems

Specifications

Documentation

Under the order

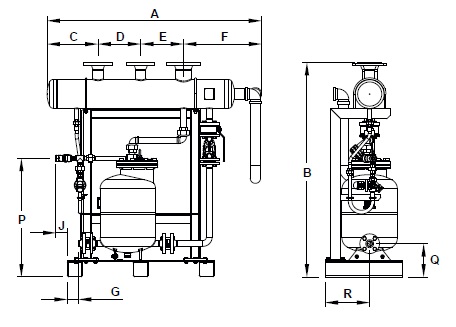

Dimensions

1"x1", 11/2"x11/2", 2"x2", 3"x2"; DN25x25, DN40x40, DN50x50, DN80x50

DESCRIPTION:

The PRIMA-THERM MSVK-1 packaged pump units can be used to lift or displace hot condensate and other liquids even in hazardous areas. The unit is comprised by an ADCAMat POP, a vented receiver and all auxiliary items, compactly mounted on a metal frame, piped and ready for connection.

Packaged units save time, work and site costs. In addition, they ensure that the installation of the pump is correct in every detail. Two or more units can be connected in parallel to cope with flow rates beyond the capacity of a single pump.

Packaged units for operation with compressed air are also available.

OPERATION:

Liquid flows by gravity into the pump through an inlet check valve, lifting the float. At this point, the motive fluid intake valve is closed while the vent valve is open. As the float reaches its highest position the motive fluid intake valve opens and the vent valve closes, allowing the motive fluid to enter the pump body. The pressure in the pump builds up just enough to overcome backpressure.

The pressurized liquid opens the outlet check valve and the discharge starts. The liquid discharged may be quantified through a special counter, enabling the pump to function as a reliable flow meter.

When the float reaches its lower position the motive fluid intake valve closes and the vent valve opens allowing the liquid to fill the pump once again, repeating the cycle.

CE MARKING – GROUP 2 (PED – European Directive)

|

Nominal pressure |

Nominal sizes |

|

PN 16 |

1'' x 1'', 11/2" x 11/2", 2" x 2", 3" x 2". |

BODY LIMITING CONDITIONS

|

Pump |

ADCAMat POP |

|

Liquid specific gravity |

0,8 – 1 |

|

Maximum viscosity |

5° Engler |

|

Max. operating pressure motives medium |

1 – 10 bar |

|

Receiver – Max. operating pressure |

0,5 bar |

|

Maximum motive inlet pressure |

10 bar |

|

Minimum motive inlet pressure |

0,5 bar |

|

Maximum operating temperature |

185 °C |

|

Minimum operating temperature |

0 °C |

|

Pump discharge per cycle |

16 L |

|

Pump discharge per cycle (sizes: 3"x2"; DN 80x50) |

25 L |

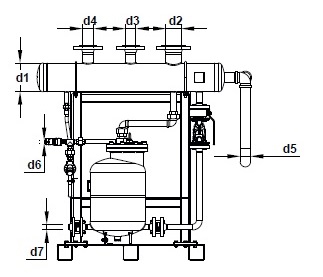

CONNECTIONS SIZE

|

Size |

d1 (mm) |

d2 * |

d3 * |

d4 * |

d5 |

d6 |

d7 ** |

|

DN 25 |

168 |

3"; DN 80 |

2"; DN 50 |

2"; DN 50 |

2" |

1/2" |

1"; DN 25 |

|

DN 40 |

168 |

3"; DN 80 |

2"; DN 50 |

2"; DN 50 |

2" |

1/2" |

11/2"; DN 40 |

|

DN 50 |

220 |

3"; DN 80 |

2"; DN 50 |

2"; DN 50 |

2" |

1/2" |

2"; DN 50 |

|

DN 80x50 |

273 |

4"; DN 100 |

21/2"; DN 65 |

21/2"; DN 65 |

2" |

1/2" |

2"; DN 50 |

d2 – vent; d3 and d4 – condensate inlets;

d5 – overflow.

* Threaded connections on request. *

* Welding neck flange. Threaded connections on request.

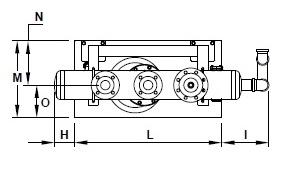

DIMENSIONS (mm)

|

Size |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

L |

M |

N |

O |

P |

Q |

R |

|

DN 25 |

1251 |

1254 |

298 |

250 |

250 |

454 |

66 |

118 |

274 |

66 |

860 |

450 |

260 |

190 |

693 |

195 |

260 |

|

DN 40 |

1251 |

1254 |

298 |

250 |

250 |

454 |

46 |

118 |

274 |

66 |

860 |

450 |

260 |

190 |

693 |

195 |

260 |

|

DN 50 |

1289 |

1304 |

316 |

250 |

250 |

473 |

32 |

136 |

293 |

72 |

860 |

450 |

260 |

190 |

693 |

195 |

260 |

|

DN 80 x 50 |

1367 |

1368 |

175 |

330 |

330 |

532 |

13 |

125 |

282 |

3 |

960 |

535 |

309 |

226 |

703 |

208 |

309 |

Dimensions subject to change without notice. Consult manufacturer for certified dimensions and weight.

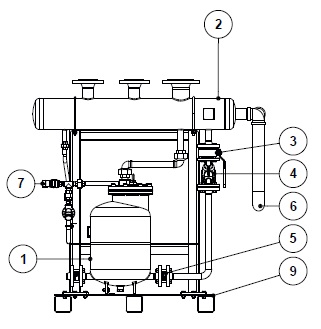

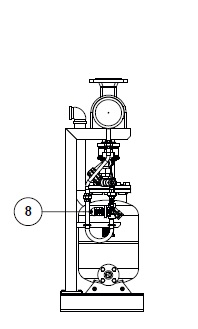

MATERIALS

|

Pos. Nº |

DESIGNATION |

|

1 |

POPS pumps (Valsteam ADCA) |

|

2 |

Receiver |

|

3 |

Ball valves (ICP Valves / Valsteam ADCA) |

|

4 |

Y-strainer (Valsteam ADCA / SFERACO) |

|

5 |

Disc check valve (ICP Valves / Valsteam ADCA / SFERACO) |

|

6 |

Overflow |

|

7 |

Y-strainer (Valsteam ADCA / SFERACO) |

|

8 |

Steam trap (Valsteam ADCA) |

|

9 |

Metal frame |

Documentation

Опитувальний лист для підбору та замовлення установки по збору і поверненню конденсата.docx

232,6 Kb

Завантажити повний опис PRIMA-THERM MSVK-1.pdf

1,9 Mb